Understanding Employee Turnover in Manufacturing

What is Employee Turnover?

Employee turnover measures the rate at which workers leave and need replacing, encompassing both voluntary and involuntary departures. The distinction matters: voluntary turnover often reflects addressable factors like culture or development opportunities, whilst involuntary separations, though sometimes necessary, still incur knowledge transfer costs. With 43% of UK manufacturers reporting hard-to-fill vacancies according to CIPD's Labour Market Outlook Spring 2025, every departure creates gaps that are increasingly difficult to fill.

Average Turnover Rate in Manufacturing

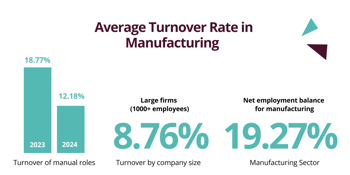

Recent data from the Labour Turnover Report reveals significant improvements:

Overall turnover trends:

- 2022: 20.75%

- 2023: 16.12%

- 2024: 10.85% (lowest in a decade)

- Excluding redundancies in 2024: just 6.24%

Turnover by role type (2024):

- Manual roles: 12.18% (down from 18.77% in 2023)

- Non-manual roles: 11.84% (down from 20.24% in 2023)

Turnover by company size:

- Small firms (10-249 employees): 13.31%

- Medium firms (250-499 employees): 9.66%

- Large firms (1000+ employees): 8.76%

Sector variations:

- Food & Drink: 5.02%

- Textiles: 14.84%

- Motor Vehicles: 15.89%

- Chemicals: 19.50%

- Other Manufacturing: 19.27%

CIPD's data shows manufacturing's net employment balance at -12, indicating more businesses expect to decrease rather than increase their workforce, making retention of existing skilled workers crucial.

Expert Insight

Emma Parkin, Head of Propositions at The Access Group, compares turnover rates across sectors and how benefits packages influence retention.

Why Manufacturing Employees Leave

In 2023, retirement accounted for 52% of manufacturing exits. The remaining departures reveal addressable issues:

Primary reasons for manufacturing employees leaving:

- Better progression opportunities elsewhere

- Poor relationships with managers

- Inadequate recognition for contributions

- Safety concerns (physical and psychological)

- Inflexible scheduling

- Compensation perceived as unfair

- Mental and physical health impacts

- Desire for sector change

These factors rarely work in isolation - employees typically leave when multiple frustrations combine with an attractive alternative opportunity.

Turnover is a major challenge for the manufacturing industry; however, it’s not the only one. For a detail discussion of other HR challenges, read our article on the 5 HR challenges in manufacturing, and discover strategies to tackle them alongside side the following retention strategies.

What Are the 10 Best Employee Retention Strategies in Manufacturing?

1. Improve Onboarding

Effective manufacturing onboarding requires clear expectations about roles and how they contribute to production goals. Pairing new starters with experienced workers through mentorship programmes accelerates skill development whilst building relationships that anchor employees to the organisation. Regular check-ins during the first 90 days identify and address issues before they become reasons to leave, whilst digital tools streamline processes across multiple sites and shifts.

Dublin Port's implementation of Access PeopleXD Evo replaced manual systems with digital workflows, improving onboarding whilst freeing HR for strategic support.

2. Build a Safe and Positive Work Environment

Comprehensive safety training that empowers workers to stop production when concerns arise demonstrates genuine commitment to wellbeing. Creating psychological safety for reporting near-misses and suggesting improvements builds trust and engagement. Investment in ergonomic equipment and comfortable break areas might seem basic but communicates respect for workers' daily experience. When teams develop supportive peer networks, employees are less likely to leave even when other opportunities arise. For ideas on the benefits and strategies to build effective peer-to-peer recognition networks, see our blog on ‘Peer-to-peer recognition ideas that make a real difference’.

3. Offer Competitive Compensation and Benefits

Whilst compensation alone rarely drives retention, uncompetitive packages certainly drive departures. Healthcare provision that includes preventive care and mental health support addresses workers' security concerns. Strong pension contributions matter enormously to the 52% of manufacturing workers approaching retirement (Labour Turnover Report). Practical benefits like transport support or childcare assistance often matter more than traditional perks, showing understanding of workers' real challenges. Transparency in compensation structures reduces perceptions of unfairness that drive departures.

"Every £1 spent on effective benefits saves £7–15 in turnover costs. For a 500-employee business, just a 10% reduction in turnover delivers £1.33 million in net ROI."

Emma Parkin, Head of Proposition at The Access Group

4. Invest in Career Development

Modern manufacturing requires sophisticated skills, creating natural progression pathways that retention-focused employers can leverage. Upskilling programmes for emerging technologies demonstrate investment in employees' futures whilst building capabilities the business needs. Cross-training across different production areas provides variety and flexibility. Apprenticeships create clear advancement routes from entry-level to skilled positions. Partnerships with educational institutions bring formal qualifications within reach, whilst visible promotion pathways based on merit and development show that advancement is achievable.

5. Strengthen Leadership and Management

The supervisor-worker relationship profoundly impacts retention. Manager training that includes people skills creates supervisors who inspire their colleagues. Stay interviews can also help understand what keeps employees engaged before they consider leaving. Our guide to enhancing employee retention with stay interviews discusses how stay interviews can improve retention. Open-door policies have to be backed by genuine action to build trust. Leadership visibility on the shop floor can break down hierarchies that can make workers feel disconnected. Consistent, fair treatment across all shifts and departments prevents the resentment that drives turnover.

6. Foster a Culture of Recognition

Peer-to-peer recognition programmes prove particularly powerful where colleagues best understand specific role challenges. Safety milestone celebrations reinforce this critical aspect of manufacturing work. Timely, specific performance acknowledgement shows genuine appreciation for individual contributions. Public recognition through multiple channels amplifies impact, whilst mixing financial and non-financial rewards ensures different preferences are met.

To explore the broader benefits and strategies behind effective recognition, read more about what employee recognition really means and how it can transform workplace culture.

7. Promote Work-Life Balance

Flexible shift patterns that allow some scheduling choice help workers manage personal commitments. Generous paid leave acknowledges the physical and mental demands of manufacturing work. Mental health support through employee assistance programmes addresses wellbeing proactively. Family-friendly policies for parents and carers help retain valuable employees who might otherwise leave the workforce.

As Emma Parkin, Head of Proposition at The Access Group notes:

"Every scheduling decision must balance legal compliance, customer commitments, and worker preferences - yet most still use systems that can't see these conflicts until they become crises."

8. Enhance Internal Communication

Multilingual messaging can help critical information reaches diverse workforces. Regular feedback loops that genuinely listen and respond to employee input build trust and engagement. Visual communication through displays and infographics suits environments where written communications might be overlooked. Team briefings at shift handovers ensure information flows consistently, whilst digital tools bridge communication gaps for dispersed sites.

9. Reframe Manufacturing Careers

Changing perceptions can help attract quality colleagues who strengthen team dynamics. Employer branding that showcases modern manufacturing reality counters outdated stereotypes. Educational partnerships bringing schools into facilities change perceptions early. Internal career stories highlighting progression from shop floor to senior positions inspire employees. Emphasising manufacturing's societal contribution helps employees feel part of something meaningful. Industry involvement through competitions and associations positions the organisation as a leader in manufacturing excellence.

10. Use HR Systems and Data Analytics

Data-driven approaches enable proactive retention strategies. Monitoring turnover trends by department, shift, and demographic reveals patterns requiring targeted intervention. Predictive analytics identify at-risk employees before they decide to leave. Regular pulse surveys provide ongoing intelligence about satisfaction and concerns. Workforce planning tools balance operational needs with employee preferences. Visible dashboards for operational managers embed retention thinking into daily management.

Turning Strategy into Action with Tools to Reduce Turnover in Manufacturing

The improvement in manufacturing turnover rates proves that thoughtful retention strategies deliver results. Success requires recognising that retention is about creating workplaces where people want to stay and contribute their best work.

With replacement costs ranging from 75% to 200% of annual salary and 43% of manufacturers facing hard-to-fill vacancies, every prevented departure delivers immediate returns whilst preserving crucial knowledge.

Implementation becomes manageable with appropriate tools. HR platforms can automate administrative tasks, provide analytical insights, and enable the employee experience that builds loyalty. Whether managing complex scheduling, delivering development programmes, or gathering feedback, technology amplifies human effort in building retention-focused cultures.

The path to improved retention starts with commitment, continues through systematic implementation of proven strategies, and succeeds through consistent execution supported by appropriate tools. For manufacturing businesses willing to invest in their people, the rewards extend beyond reduced turnover to improved productivity, stronger customer relationships, and sustainable competitive advantage.

Ready to transform your manufacturing retention rates?

Our HR Software provides integrated platforms for managing onboarding workflows through to predictive analytics.

Access Employee Engagement Software enables recognition, communication, and feedback strategies

Access HR Solutions for Manufacturing address specific challenges of scheduling, compliance, and workforce planning

AU & NZ

AU & NZ

SG

SG

MY

MY

US

US

IE

IE