Sage 200 Manufacturing End of Life: What Happens Next?

Sage 200 Manufacturing End of Life: What Happens Next?

Sage has officially declared end of life for the Sage 200 Manufacturing Module; support for the module will not be provided after 31 December 2025.

If your business uses Sage 200 Manufacturing, now is the time to plan for this major change and consider your options. Don’t risk system failures, compliance headaches or security vulnerabilities.

What does this Sage 200 Manufacturing end of life process mean for my business?

The manufacturing functionality will only be available, without support (including big fixes, legislative updates, security patches) if you’re running an older version of Sage 200.

If you choose to upgrade to version 2025 R2 and beyond, you will need to start exploring your options now.

The best alternative to the Sage 200 Manufacturing Module

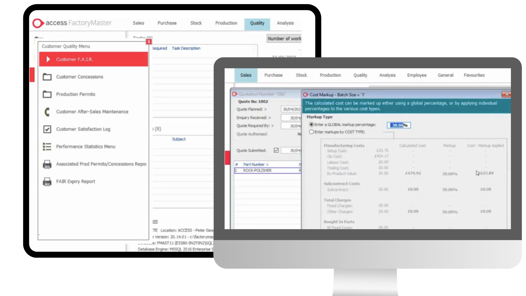

Access FactoryMaster is a Sage 200 Manufacturing alternative which offers functionality that exceeds what you’re used to with Sage.

Our modular MRP software is purpose-built for small to mid-sized manufacturers - it’s not a financial system with a manufacturing module bolted on like Sage.

What makes Access FactoryMaster stand out from Sage 200 Manufacturing?

- Direct support from Access:

Unlike Sage’s partner-led model, Access builds and implements Access FactoryMaster, ensuring faster support, clearer accountability and consistent pricing

- Deployment flexibility:

Access FactoryMaster is available both cloud-based and on-premise, giving you full control over deployment - a critical factor in regulated or infrastructure sensitive industries

- Modern, modular and manufacturer-first:

Access FactoryMaster is designed solely for manufacturers and offers a user-friendly, intuitive interface, fast deployment, and deep MRP functionality without the legacy complexity of Sage 200

- We grow with our customers:

Access FactoryMaster can handle increasingly complex workflows and connect into your wider eco-system, making Access a true partner for growth

Feature Comparison

See the software in action

Why our customers love Access FactoryMaster

Next Steps

If you want to talk to our team about your specific requirements, have questions about Access FactoryMaster or just want to learn more, get in touch with us today.

FAQs

We’re already using the Sage 200 Manufacturing Module — we’ll just migrate to CIM 200.

CIM 200 is a third-party solution, not a native Sage product. Migration still involves cost, disruption, and retraining — so now is the ideal time to evaluate Access FactoryMaster.

We like Sage, it’s familiar and our team knows how to use it

Familiarity is helpful, but Sage’s interface is often described as outdated and clunky. Access FactoryMaster software offers a better user experience, reducing training time and improving usability.

We need both cloud and on-premise options — Sage gives us that

Access FactoryMaster also supports hybrid deployment — but with a cloud-first design that delivers better performance, scalability, and compliance for regulated industries.

We trust Sage’s partner network — they’ve always supported us

Sage’s partner model can lead to inconsistent pricing and support. With Access, you’re working directly with the vendor, ensuring faster support, transparent pricing, and full accountability.

CIM 200 is integrated with Sage 200 Professional — it’s a complete ERP

CIM 200 is still a bolt-on to a legacy system. Access FactoryMaster is built for manufacturers first and integrates with Access Financials and other modules for a unified ERP experience.

AU & NZ

AU & NZ

SG

SG

MY

MY

US

US

IE

IE