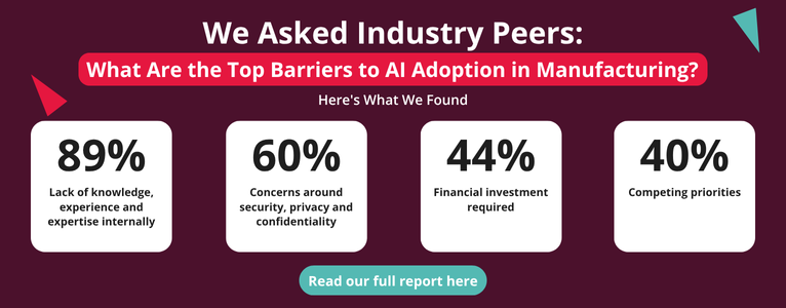

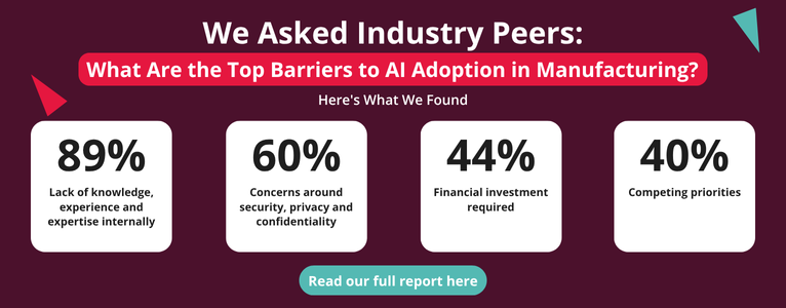

Despite the optimism surrounding deploying AI in manufacturing, few companies are on their way to reaping the rewards of this technology. In the UK, manufacturing is the sector least likely to use AI technology already, pointing to a major gap between adoption and understanding of its full capabilities.

Among the common barriers to AI adoption in the manufacturing sector are employees' lack of technical knowledge and trust in AI in general. These barriers align with some of the technology's well-known risks and perceived downsides of AI in manufacturing.

Data security and integrity

Advanced machine learning models are built on vast amounts of data. While data collection is the norm in digital-forward manufacturing companies today, using large datasets to train AI can introduce significant cybersecurity risks.

In a worst-case scenario, data breaches can cost companies millions in penalties from organisations like the Information Commissioner's Office (ICO). Plus, there are increased risks of data leaks via AI models trained internally on confidential company data, which could easily compromise company performance if disclosed.

Poor quality data inevitably results in poor AI recommendations and solutions, and without confidence in the original data, building AI solutions can be a costly waste of time.

The cost of adopting AI

Cost is of particular concern for SMEs. Given increased costs across the supply chain, particularly in energy and raw materials, many companies will naturally hesitate to invest in AI, especially if the ROI and benefits are unclear.

Despite these significant obstacles, many companies are experimenting with AI in manufacturing, and in some areas of operation, the benefits undoubtedly outweigh the disadvantages.

AU & NZ

AU & NZ

SG

SG

MY

MY

US

US

IE

IE