Warehouse Management System (WMS)

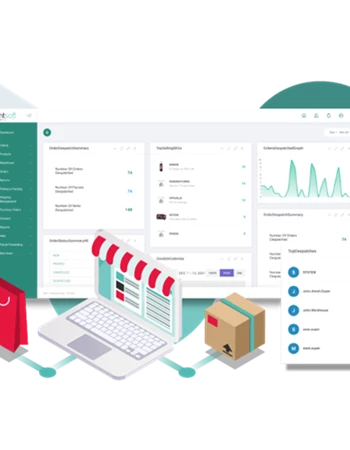

Access Mintsoft is our leading warehouse management system (WMS) designed for 3PL warehouses, wholesalers and eCommerce operations in Australia and New Zealand. Our cloud-based warehouse management software will significantly improve your warehousing order and inventory management through intelligent automation.

WMS trusted by over 600 organisations

Intergrated cloud based Warehouse Management Software

Real Time Reporting

Gain confidence in your business with real-time reporting on orders, inventory, and shipments.

Optimise Warehouse Space

Optimised location management helps maximise the space you have.

Streamline Warehouse Management

Take your workflow management to the next level with features that automate pallet and carton handling, stock counting, and cycling.

Powerful Automation

Help operators work more efficiently by automating tasks and processes and providing real-time updates.

The leading WMS for warehouses, wholesalers and ecommerce

Whether you’re a B2B or B2C business, our software can be tailored to suit your needs. Mintsoft warehouse management software will help you pick, pack and ship your products across Australia and beyond, with incredible accuracy.

Transform your warehouse efficiency with Mintsoft

Improve efficiency with barcoding software

- Multi-type Barcode Picking: Multiple types of batch driven barcode picking are available within the app to suit the types of orders in logical location order for maximum efficiency and 100% accuracy.

- Goods-in Processing: Our app makes your goods in process fast, simple and accurate. Book stock easily and receipt and reconcile against pre-existing ASNs or Purchase Orders.

- Transfer Stock: Seamlessly move stock from one location to another - either full pallets or individual units.

- Location Stock Adjustments: Simply scan a location ID to make quick stock adjustments or all SKUS - up or down. The app is incredibly quick at taking control of mixed variant SKUs held in pick bins after a stock take.

Advanced multi-location management

- Multiple Stock Locations: Assign multiple stock locations to individual product lines for pick management, replenishment and bulk storage. Location zone management helps to split and divide picking tasks efficiently across your warehouse workforce.

- Location Labelling: Bulk print location ID barcode labels in any format & size for thermal or laser printers.

- Customisable Location: Types Allocate customised location types to your location IDS to suit your setup such as Pick Bins, Standard Pallets, Double Size Pallets. Location types rules can be set up for storage billing and automatic stock allocation.

- Location Capacity: Instantly view aisle by aisle capacity on an interactive grid and location type capacity from via a dashboard widget.

Advanced warehouse management

- Tasking/Workflow Management - Control who and how larger, more complex picks are handled.

- Pallet & Carton Support - Regulatory compliance with GS2 coding to support picking of pallets and cartons.

- Work zones & areas - Further grouping of warehouse locations to include zones & areas.

- Quality Control - Quality checking of inbound and outbound goods to ensure stock moving in and out of warehouse meets required standards.

- Units of Measure & Volumetric support - Stock capacity management by various units of measure and volume.

- Advanced Task Automation - Replenishment, receipt & putaway rules, and picking.

Specialist warehouse inventory tracking

Designed to be flexible, our warehouse inventory management software can accommodate specialist inventory types - such as perishable goods.

- Best Before Dates:Mintsoft provides automatic FIFO stock allocation management for perishable products with custom expiry date warning notifications.

- Take control of batches and lots: Ensure every piece of inventory that flows through your warehouse can be tracked to its group of origin by tracking which batches have been sent to specific customers in case of product recall events.

- Serial Numbers: Incorporate individual serial number tracking for high value goods on outbound despatch - such as IMEI numbers for high end mobile phones.

- Full Audit Trail: All stock transactions are fully auditable. Every stock transaction is stored with the order ID, customer name and operator that committed the action. These are all easily exportable to excel for reconciling.

Success Story

As an eCommerce 3PL specialising in smaller consumer items, such as clothing and cosmetics, Black Bear Fulfillment are 100% Australian owned and operated. Unlike most 3PL’s they aren’t just focused on the logistics and warehousing side of the business, but also, importantly, the customer. Fulfillment is about people as much as it is logistics, and they needed a software solution to help bring this customer-centric vision to life.

I would recommend Mintsoft to anyone - except my competitors

Mack Blunsom: Owner Operator, Black Bear Fulfillment

What our customers say about our Warehouse Management System

Get more from your WMS

Get in touch with one of our ERP specialists to find out how Access Mintsoft can help in managing your organisation's unique needs.

Our solutions beyond Warehouse Management Software

Warehouse Management Resources

The latest resources to help you get the most out of your warehouse management software.

Warehouse Management System FAQ

What is a Warehouse Management System?

A Warehouse Management System (WMS) is software designed to optimise and manage warehouse operations efficiently. It helps track inventory, control movement, and enhance order fulfillment. Designed to support both B2B and B2C warehousing operations - whether you’re a small-scale fulfilment house, or an established multi-warehouse (or somewhere in between) – our warehouse management software is the go-to solution for ensuring business continuity.

How much does a warehouse management system cost?

According to the most recent data provided by Software Path, the average expense associated with a warehouse management system totals approximately $14,000 AUD per individual user when calculated over a five-year span. On a monthly basis, this translates to an average cost of approximately $240 AUD per user.

However, it's important to note that when calculating costs per user, this figure doesn't encompass the overall expenditure when factoring in the number of users who require access to the software. Consequently, it is likely that your warehouse management system (WMS) will range from $15,000 to $30,000 AUD, depending on factors such as the size of your warehouse or warehouses, the number of users, and whether mobile barcode scanning capabilities are needed.

The positive aspect is that, at Mintsoft, we do not impose user limits, thus avoiding any additional expenses tied to the number of system users. Instead, we offer a pricing structure that scales in tandem with your order volume, allowing our clients to expand their operations without putting their cash flow at risk. You can check out our detailed pricing guide: How much should my business pay for Warehouse Management Software?

How does a Warehouse Management System work?

A WMS uses barcode scanning, RFID technology, and software algorithms to track inventory, manage storage locations, and optimise picking and packing processes for improved efficiency. This system helps manage warehouse operations effectively:

- User Access Control: Access groups determine who can perform various tasks and access specific areas within the WMS. This ensures authorised personnel handle critical functions while restricting unauthorised access.

- Inventory Management: WMS oversees inventory by tracking goods, maintaining real-time stock levels, and optimising storage. Access groups regulate who can view, edit, or modify inventory data, with warehouse supervisors having comprehensive access and staff having limited access.

- Order Management: WMS streamlines order processing, including picking, packing, and shipping. Access groups assign tasks to authorised users or groups, enhancing operational efficiency and security by preventing unauthorised access.

What is the difference between WMS & OMS?

Warehouse Management System (WMS): A software solution designed to streamline and optimise warehouse operations. Its core focus is on efficiently managing the physical aspects of a warehouse. This includes tasks such as inventory tracking, storage location management, order picking and packing optimization, real-time stock visibility, and the efficient allocation of warehouse resources.

Order Management System (OMS): A software solution that centres on managing and optimising the end-to-end order fulfillment process. Its primary goal is to ensure that customer orders are processed accurately and efficiently. OMS handles tasks like order capture, order processing, payment processing, inventory allocation, shipment scheduling, and customer communication.

In essence, WMS is about managing the physical aspects of the warehouse, while OMS focuses on managing the entire lifecycle of customer orders, from the moment an order is placed to its successful delivery. Both systems play critical roles in modern supply chain management, and their integration can lead to improved overall efficiency and customer satisfaction.

Who can benefit from a Warehouse Management System?

A Warehouse Management System (WMS) can benefit a wide range of businesses and organisations. Retailers and e-commerce companies can use WMS to efficiently manage inventory and ensure accurate order fulfillment. Manufacturers can streamline production processes and reduce delays by integrating inventory management with WMS. Distributors, wholesalers, and third-party logistics providers can optimise inventory control and distribution. Industries with specific compliance needs, such as food and pharmaceuticals, can maintain regulatory requirements. Healthcare facilities can improve supply chain operations, while automotive and textile businesses can enhance inventory management for various product lines. Essentially, any organisation dealing with inventory, warehousing, and order fulfillment can benefit from a WMS. It enhances operational efficiency, minimises errors, improves inventory accuracy, and ultimately leads to better customer service.

Is Your Warehouse Management System Cloud-Based?

Yes, The Access Group offers a cloud-based Warehouse Management System (WMS) solution. Our cloud-based WMS Mintsoft provides several advantages, including scalability, accessibility from anywhere with an internet connection, and automatic updates to ensure you're always using the latest features and security enhancements. This approach reduces the need for on-premises hardware and simplifies system maintenance.

Is ERP the same as WMS?

A WMS is designed to automate, optimise and improve warehouse operations, whereas Enterprise Resource Planning (ERP) is the automation of processes across all areas of a business, from human resources to procurement.

WMS can be used for both small and large warehouses but comes into its own with floors of over 20,000 square feet and the demands placed upon start to get complex. At this level and above it is sometimes referred to as an ERP system or enterprise resource planning.