New HVAC Regulations 2025: A Guide to Navigating the AIM Act for Commercial HVAC Contractors

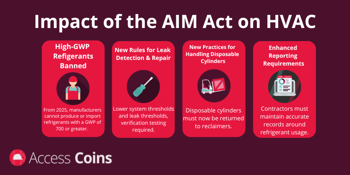

New HVAC regulations in 2025 have significantly changed operations for commercial HVAC contractors across the United States. The Environmental Protection Agency (EPA), through the American Innovation and Manufacturing (AIM) Act, includes the phase-down of hydrofluorocarbons (HFCs) like R-410A.

Starting in 2025, contractors cannot manufacture or import HVAC products using refrigerants with a Global Warming Potential (GWP) of 700 or higher.

The EPA has also mandated stricter leak detection protocols and repair timelines for systems containing 15+ pounds of refrigerant.

This guide offers practical steps for compliance – including the tools needed to help with recordkeeping requirements.

Decoding the AIM Act - What Commercial HVAC Contractors Need to Know

The American Innovation and Manufacturing (AIM) Act represents the most significant federal regulation affecting HVAC operations in years.

Contractors who understand these regulations will gain a competitive advantage while avoiding potential penalties and business disruptions.

The Phase-Down of High-GWP Refrigerants

The EPA has established an ambitious schedule to reduce HFC production and consumption in the United States by 85% by 2036. As part of this phasedown, a 40% reduction below baseline levels is in effect from 2024 through 2028. Annual allowances for HFC production and import are issued for each calendar year and are valid only within that year.

From 2025 onwards, manufacturers cannot produce or import new HVAC systems using refrigerants with a GWP of 700 or greater. Popular refrigerants affected include R-410A (GWP 2,088), R-404A (GWP 3,922), and R-134a (GWP 1,430).

A grace period permits installation of systems with components manufactured or imported before 2025 through the end of that year.

For contractors, these changes create two distinct scenarios. New installations must use low-GWP alternatives like R-32 (GWP 675) or R-454B (GWP 466). Servicing existing systems with high-GWP refrigerants remains allowed, though supply will decrease and costs will likely rise as production limits tighten.

New Rules for Leak Detection and Repair

The EPA has also implemented significantly stricter inspection and repair requirements for refrigeration systems.

- Lower System Threshold

Systems with just 15+ pounds of HFC refrigerant (GWP >53) now require regular inspections, down from the previous 50-pound minimum.

- HVAC-Specific Timelines

Comfort cooling systems must be repaired within 30 days when annual leak rates exceed 10%.

- Commercial & Industrial Thresholds

Commercial refrigeration follows a 20% leak threshold, while industrial process refrigeration allows up to 30%.

- Verification Requirements

All repairs need verification testing and follow-up inspections to confirm resolution.

- Automatic Detection Systems

Systems with 1,500+ pounds of high-GWP refrigerant must install continuous monitoring equipment. New systems require immediate compliance, and existing systems need retrofits by 2026.

Managing Disposable Cylinders

The AIM Act also introduces new practices for handling refrigerant containers. Instead of throwing away disposable cylinders, they have to return them to reclaimers. The process recovers leftover refrigerant (called "heel").

The goal is to prevent refrigerant release into the atmosphere and reduce environmental harm. HVAC contractors should establish connections with certified reclaimers and create processes for collecting, storing, and returning used cylinders as part of regular operations.

Enhanced Record-Keeping and Reporting

Documentation demands have expanded considerably under the AIM Act. Contractors must maintain accurate records about refrigerant usage, leak inspections, repairs, and equipment tracking.

Technicians and equipment owners are responsible for documenting service activities, leak calculations, and refrigerant recovery throughout equipment lifecycles.

Federal reporting becomes necessary in specific situations. Equipment leaking 125% or more of its charge within a calendar year requires formal notification to authorities by March 1 of the following year.

Penalties for non-compliance have increased - alongside more frequent audits and inspections.

Digital construction document management systems, such as a Construction ERP, provide valuable benefits for fulfilling these increased documentation needs.

Centralize Construction Documents and Data with Access Coins

Access Coins, the ERP purpose-built for construction, provides a single source of truth for your data.

Actionable Steps for AIM Act Compliance for HVAC Contractors

Because of the AIM Act, commercial HVAC contractors must enact considerable operational changes. The following strategies help contractors meet regulatory requirements and maintain a competitive advantage during this industry transition.

Planning for the Refrigerant Transition

Technician education stands as a top priority for HVAC companies. Low-GWP refrigerants like R-32 and R-454B have different handling requirements, pressure characteristics, and safety considerations compared to traditional options.

Many of these alternatives have mild flammability ratings (A2L), requiring updated safety protocols. Formal training programs, like EPA-recognized Low-GWP Refrigerant Safety certification courses, give technicians the knowledge needed for safe, compliant operations.

Documentation for these safety certificates can then be saved and aligned to technicians using construction workforce management software. Dispatchers can then ensure technicians with the correct training are sent to relevant jobs using mobile apps and field service management software.

Equipment compatibility presents another challenge. New refrigerant types often demand different tools, gauges, recovery machines, and leak detectors.

Creating an inventory of current equipment and identifying compatibility gaps allows for strategic upgrading plans. Equipment tracking software helps monitor which tools need replacing and which can be adapted to multiple refrigerant types.

Smart inventory management during the transition period requires a balancing of stockpiles. Maintaining enough traditional refrigerants to service existing systems while gradually building an inventory of new alternatives will help prevent service disruptions.

Careful documentation of refrigerant quantities, storage locations, and projected usage rates enables more accurate purchasing decisions during this period of market uncertainty.

Implementing Strong Leak Detection and Prevention Programs

Regular inspection schedules form the foundation of effective leak management. Smart contractors now include mandatory leak checks in all standard maintenance contracts, creating both compliance value and new revenue opportunities.

For systems with 15+ pounds of refrigerant, quarterly inspections help catch minor issues before they trigger regulatory violations. Clear documentation templates should accompany each inspection to streamline the process. HVAC contractors using a modern construction ERP system can create custom inspection forms to standardize this process.

Modern detection technology makes finding small leaks faster and more reliable. Ultrasonic detectors, infrared cameras, and electronic sniffers each offer advantages for different system types and environments.

Planning for automatic leak detection systems is a good idea for systems with 1,500+ pounds of refrigerant, with a 2026 deadline around the corner. Early adoption minimizes business disruption and demonstrates regulatory commitment to commercial customers.

Service teams need to be trained on repair verification techniques, including pressure testing, vacuum testing, and observation periods. During audits, training programs focusing on technical skills and documentation help guarantee that inspection records adhere to regulatory standards.

Streamlining Refrigerant Management and Disposal

Under the new standards, efficient refrigerant handling procedures are significant for both cost control and compliance.

- Recovery Efficiency

Equip each service vehicle with properly rated recovery equipment matched to specific refrigerants. Create step-by-step recovery procedures for technicians and establish partnerships with EPA-certified reclaimers who may offer credits for returned refrigerant.

- Cylinder Logistics

Designate storage areas for used disposable cylinders awaiting return. Track serial numbers and contents for custody documentation and schedule regular reclamation facility pickups. Consider supplier cylinder exchange programs to simplify the return process.

- Digital Record Management

Track refrigerant from purchase through usage to final disposition. Document equipment serviced, quantities added or removed, and recovery amounts. Implementing a modern ERP system acts as a single source of truth, with mobile applications allowing technicians to input data directly from the field.

Communicating Changes to Commercial Customers

Proactive customer education sets leading contractors apart. Create clear summaries of the impact of the AIM Act and share them through email, customer portals, and during service visits.

Use your CRM to segment communications based on equipment types, targeting owners most affected by the changes. Schedule brief meetings for facility managers with larger systems to address their specific concerns.

Beyond compliance, discussions should concentrate on the benefits of modern technologies. Studies show that retrofitting systems with low-GWP refrigerants such as R-448A and R-449A can result in energy savings of 10 to 15% compared to high-GWP refrigerants such as R-404A, helping to offset transition costs.

Plus, these refrigerants have a far reduced global warming potential, resulting in considerable carbon footprint reductions.

Cost transparency builds trust. Present clear service options highlighting the increased expenses associated with maintaining older systems, which can lead to significantly higher energy and maintenance costs over time compared to modern, compliant equipment. When technicians access customer equipment history through CRM systems on-site, they can show actual maintenance costs versus replacement savings.

Provide simple replacement guidelines that contrast the long-term costs of maintaining old equipment with those of investing in new, energy-efficient systems. Include details about available financing alternatives, state and municipal rebates, and federal tax credits that can all assist in defraying the cost of upgrades. The overall savings will change depending on specific programs and qualifying requirements.

Leveraging ERP Technology for AIM Act Compliance

Modern Construction ERP systems offer practical solutions for managing challenging AIM Act requirements. These integrated solutions help HVAC contractors transform compliance challenges into operational advantages while minimizing administrative burdens.

Streamlining Procurement of Compliant Materials

Procurement modules within ERP systems help companies comply with AIM Act regulations by filtering refrigerant options based on GWP values.

The software can be configured to flag non-compliant products during the purchasing process, automatically alerting staff when they attempt to order refrigerants with GWP values exceeding the AIM Act's 700 threshold.

ERP platforms can also forecast future inventory needs based on historical usage data, helping contractors gradually shift purchasing patterns toward compliant alternatives.

Vendor management features enable contractor qualification of suppliers based on regulatory knowledge. Buyers can flag preferred vendors who demonstrate compliance expertise and offer low-GWP alternatives.

Store manufacturer documentation within your system for quick reference when questions arise. Advanced ERP systems also allow sharing regulatory requirement documents directly with vendors, ensuring alignment on compliance expectations.

Improved Record-Keeping and Reporting for Compliance

Digital tracking via mobile apps for HVAC field crews replaces error-prone paper records with systematic documentation of all refrigerant movements. It links refrigerant usage directly to specific customer equipment and service tickets, creating complete audit trails.

Job logs also show quantities, technicians involved, recovery amounts, and disposal methods, all searchable by date, customer, or equipment type.

Automated reporting tools transform complex refrigerant data into clear compliance documentation. Schedule regular inventory reconciliation reports comparing purchased quantities against usage and recovery.

Service history tracking also creates systematic equipment lifecycle documentation. Record every refrigerant addition with precise quantities, creating automatic leak rate calculations over time.

Users can also tag certain activities as compliance-related for faster retrieval during audits. Some systems allow automatic flagging of equipment reaching leak thresholds requiring EPA reporting, preventing missed deadlines and potential violations.

Optimizing Technician Workflows for Compliance

Modern mobile technology helps technicians meet the new AIM Act requirements efficiently while also improving documentation accuracy.

- Mobile Reference Libraries

Equip field staff with digital access to refrigerant specifications, handling procedures, and safety protocols through smartphones or tablets, including offline access and calculation tools for proper refrigerant charging.

- Digital Inspection Checklists

Implement step-by-step workflows customized for different equipment types, ensuring consistent leak detection protocols and proper sequence of compliance activities.

- Photo and Video Documentation

Require images at critical inspection points, storing them directly with service records to prove compliance during audits.

- Automated Data Capture

Use barcode scanning for refrigerant cylinder tracking and digital signatures for service verification, eliminating manual recording errors.

Enhanced Communication with Commercial Customers Regarding Regulations

Modern ERP systems offer CRM tools and client portals to inform clients about regulatory impacts on their equipment. Strategic customer segmentation allows contractors to categorize clients by system size, refrigerant types, and compliance deadlines.

Equipment-specific notifications explain how their systems will be affected, focusing outreach efforts on customers most affected by upcoming changes.

Automated compliance alerts let you handle time-sensitive deadlines without tracking them manually. Along with routine service reminders, contractors can program messages tailored to individual pieces of equipment for regulatory milestones and maintenance due dates.

Customer portals offer clients 24/7 access to compliance resources, equipment specifications, refrigerant history, and maintenance records.

Personalized dashboards display regulatory status and upcoming requirements, helping facility managers plan for upgrades while enabling direct scheduling of compliance-related maintenance.

Turn the AIM Act into Your Business Advantage with Access Coins

The AIM Act has transformed HVAC operations in 2025, mandating new refrigerant standards and documentation practices.

Alongside updating equipment and training field staff, using a modern construction ERP to track compliance, improve documentation and alert clients will help your team handle the transition.

UK

UK

AU & NZ

AU & NZ

SG

SG

MY

MY

IE

IE