Big Data in Construction Management — Why Quality Data is Your AI Launchpad

Construction managers face a number of frustrating challenges, from project delays and cost overruns to slow, paper-based bureaucratic processes. These challenges often lead to reactive decision-making, rather than making proactive choices that strike at the core of the problem.

Implementing the use of ‘big data’ in construction management helps leaders break through these blockers to operate more efficiently.

Big data refers to large, complex datasets that go beyond traditional processing capabilities. It’s a transformative force that creates a base for AI technology and supports reliable automation.

In this article, we’ll explore how construction management can leverage big data to begin the shift towards smoother, AI-powered operations.

The Importance of Big Data in Construction

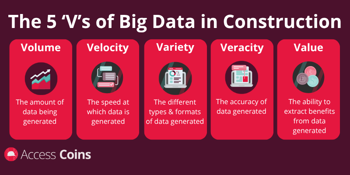

In the context of construction, big data starts with the five Vs: collecting a large Volume and Variety of data from Various sources with Velocity and Veracity.

This includes data collected from your construction sites, such as purchase orders, GRNs, data from equipment sensors, schedules and timesheets, and safety reports, alongside design and financial data.

Construction data has incredible strategic value for businesses that are looking to grow. By analyzing big data, construction leaders can pinpoint areas for improvement in their operations and help future construction projects run more efficiently.

Gaining the Competitive Edge with Data-Driven Decisions

Developing a data-driven culture helps construction organizations shift from reactive to proactive decision-making.

Some of the ways that a data-driven culture can give construction teams a competitive edge include:

- Better bidding: AI-powered tools use data from past projects to generate accurate bids that win contracts.

- Optimized resource allocation: Data analysis helps project managers fine-tune inventory management, equipment management and employee scheduling to ensure every resource is used to the fullest.

- Proactive risk management: With the right data, project managers can identify and correct risks present on their sites before they escalate into safety issues.

Using Big Data in Construction for Improved Performance

Implementing big data in construction operations can improve a company’s overall performance across every part of the construction lifecycle.

- Cost control: Track expenditures in real-time to identify areas where spending can be cut. Advanced data analysis saved global construction projects $1 billion in 2024.

- Schedule optimization: Proactively identify and address possible delays before they happen to keep projects on schedule.

- Resource management: Allocate labor, materials, and equipment to job sites, ensuring that no resources go to waste.

- Improved quality: Use data to identify possible errors or defects and address them before the project ends.

- Improved safety: Correct on-site safety risks and schedule predictive maintenance to protect teams while they’re working on-site.

Why Big Data Remains Unused Across Construction

Using big data offers undeniable value for construction companies, enhancing efficiency while keeping costs down. However, the majority of construction companies don’t have the necessary processes in place to collect, process, and analyze data across their operations.

Siloed Systems and Disconnected Data Sources

Many construction teams rely on multiple disconnected software programs to manage their operations, rather than keeping all their data in one integrated platform.

For example, a project manager may hold inventory data in a spreadsheet, scheduling in a project management tool and financial data in their accounting software, with no integration between these platforms.

82% of enterprises across industries report that data silos interrupt critical workflows. These siloed systems make it very difficult to identify patterns and connections between your data and leads to fragmented or redundant reports.

Over time, these data issues hold your organization back from optimizing your processes and operating efficiently.

Manual Processes and Human Error

Many construction companies still rely heavily on manual processes to stay organized. Manual data entry is prone to human error that can negatively affect construction operations.

This often happens when organizations have teams of seasoned employees who have been relying on the same processes for many years. In this scenario, it might feel daunting to switch from manual to automated data management.

Lack of Standardized Data Collection

For large-scale construction companies, standard data management practices are necessary for clean, consistent records. However, many construction companies don’t have data management policies, which leads to a variety of formats and naming conventions across documents.

This inconsistency makes it very difficult to properly aggregate data into big data tools. Inconsistent data also interferes with analysis, as it’s difficult to properly track trends and patterns when data is inputted in different formats.

Short-Term Thinking in Construction

Many construction teams prioritize immediate project delivery, rather than thinking long-term about strategic data accumulation. This short-term thinking often happens because teams are struggling to meet projected project timelines and budgets.

However, investing time in data management and strategic planning helps construction teams work more efficiently in the long run. With big data analysis, construction teams can plan schedules more effectively to avoid delays, or use historical cost data to forecast future budgets.

Achieving a ‘Single Source of Truth’ With Construction ERP

The best way to solve these blockers around big data analysis is to create a “single source of truth” for data across a construction company. This means storing all construction data in a single, centralized location that all departments and on-site teams across the organization can access.

The easiest way to do this is by implementing a construction-focused ERP, or Enterprise Resource Planning system. An ERP consolidates all critical business data into one platform, including financial, HR, project management, supply chain, and equipment data. Rather than having this data spread across different files and platforms, all data across operations becomes available at-a-glance.

Construction ERP also uses machine learning and automation to process big data sets. These platforms integrate with existing systems to automatically collect and structure data from key touchpoints. This ensures that the data is organized and consistent, with minimal input needed from team members. Many ERPs also use big data analysis to identify data trends and patterns and provide insights to improve construction operations.

The Benefits of a ‘Single Source of Truth’ for Construction Data

- Switching to a construction ERP offers countless benefits for construction operations. These include:

- Data consistency and accuracy: An ERP eliminates repeat data or discrepancies between entries. Automatic data collection improves data integrity for more accurate reporting and insights.

- Real-time visibility: Construction leaders get an up-to-the-minute view of what’s happening across the organization. This holistic view of operations helps them find and solve problems quickly.

- Enhanced collaboration: An ERP eliminates departmental silos, helping teams across an organization work collaboratively.

- Reduced manual effort: A construction ERP automates data flows to save teams time and limit the risk of manual errors.

- Improved compliance: An ERP makes compliance audits easier, as all necessary data is stored in one convenient system. Records are centralized and fully traceable to help construction teams adhere to industry regulations.

Big Data as a Launchpad for AI in Construction

It is undeniable that AI technology has the power to transform the construction industry. However, before construction companies can make the shift to AI-powered operations, they need to build a strong data foundation. AI systems can only run effectively when they have access to high-quality, structured data inputs.

The “Garbage In, Garbage Out” Principle in the Age of AI

The quality of an AI model is heavily dependent on the data it’s trained on. If a company powers its new AI tools using poor-quality data, the outputs will reflect that. Failing to use clean, structured data could lead to unreliable and inaccurate insights. This makes it difficult to scale AI usage and could lead to distrust of AI among construction teams and clients.

How High-Quality, Structured Data Powers AI

Here are some of the ways that quality data powers AI operations in the construction industry:

- Machine learning readiness: Machine learning algorithms learn from robust data sets. With extensive, accurate data collected across construction companies, teams can build high-performing machine learning models to support operations.

- Predictive analytics: AI tools rely on accurate historical data to forecast future costs and schedules. For example, leaders can use big data analytics to predict possible cost overruns, equipment depreciation, or project delays ahead of time, so project managers can take action. However, in order for predictive analytics to work properly, companies need to provide their AI model with a large backlog of data from past projects.

- Automation: AI is very helpful for automating repetitive tasks like quality control. For AI automation to produce high-quality results, companies need to provide reliable and consistent inputs.

- Generative AI: These sophisticated AI models are capable of generating complex reports and help engineering teams in the design process. These models require extensive training on large, detailed data sets to produce quality results.

Examples of AI Applications Enabled By Quality Construction Data

Construction teams have already found many ways to use AI to operate more safely and efficiently.

Here are some of the most exciting data-driven AI applications for the construction industry.

- Automated project scheduling: Rather than working out complex schedules manually, construction teams can use AI to generate a schedule automatically. AI tools could assess data like labor availability, historic weather conditions and timeframes from past projects to create realistic and achievable schedules.

- Predictive maintenance: AI can analyze data from equipment sensors and past equipment logs to predict when machinery will need maintenance. This gives teams the opportunity to schedule service before the important equipment breaks and prevents project delays.

- Early warning systems for risk: AI systems can process data in real-time to identify anomalies. This helps teams catch possible safety or quality risks and address them before the project is completed.

- Intelligent procurement: AI uses historical data and market trends to optimize purchasing decisions for the most effective use of procurement budgets.

Access Coins is Your Single Source of Truth for Construction Data

Access Coins is an integrated ERP platform - purpose-built for construction - that provides a single source of truth for your data across projects and teams.

UK

UK

AU & NZ

AU & NZ

SG

SG

MY

MY

IE

IE