Manufacturing software

Manufacturing software from The Access Group brings a new view of your business performance and data, including powerful collaboration tools and real-time dashboards that increase efficiency and productivity to inform quicker, more effective decision-making.

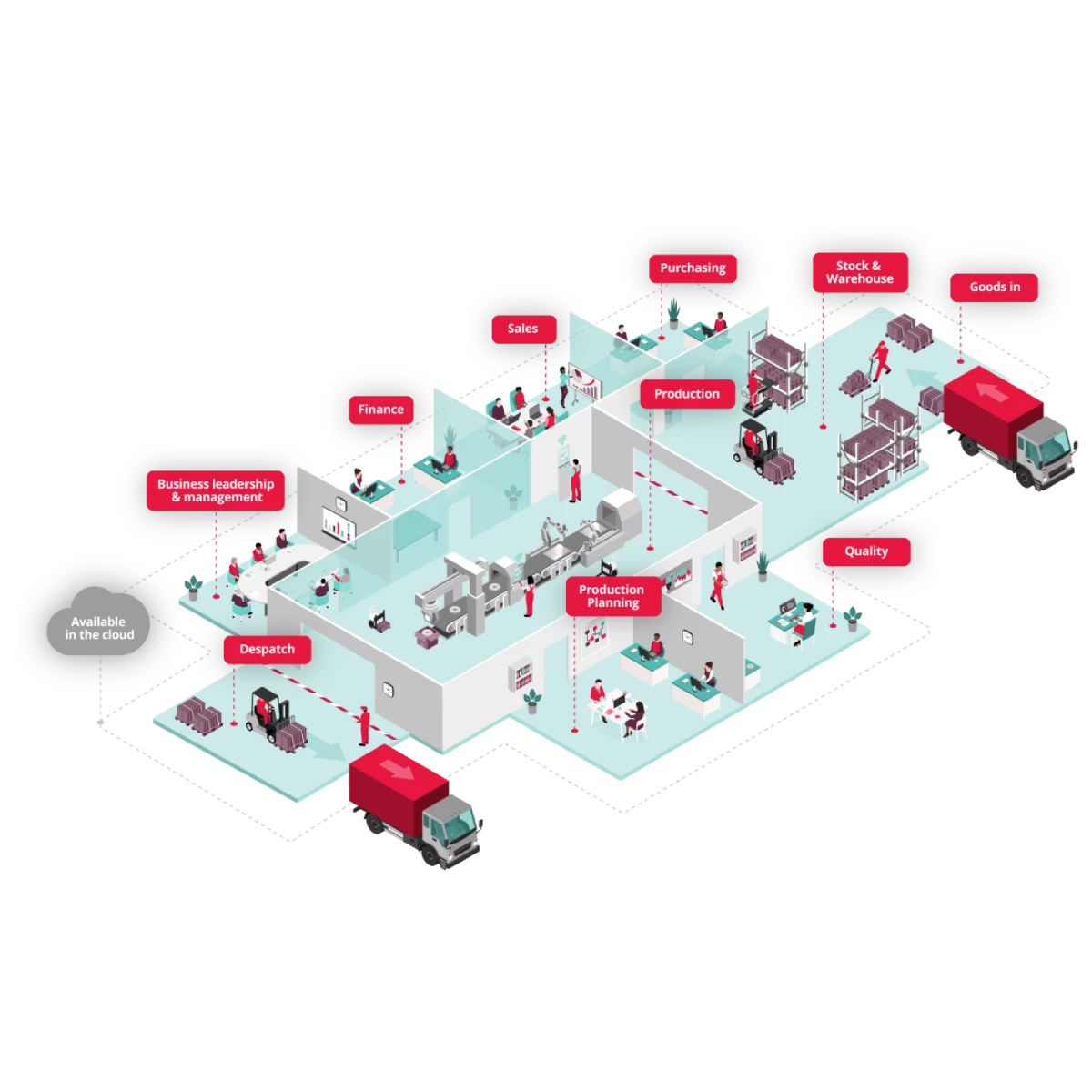

End-to-end manufacturing software

Boost your bottom line by integrating your data and systems and automating manual, paper-based and spreadsheet-based processes with Access Manufacturing software.

Our cloud-based manufacturing software is designed to join the dots across your manufacturing operations: material requirements planning (MRP), production planning & scheduling, business management, operations management, reporting and analytics and more.

We serve a number of manufacturing sectors, including pharmaceutical, aeropsace, automotive, metal fabrication, precision and specialised engineering, food and drink and much more.

Why choose integrated manufacturing software?

Access Manufacturing software is trusted by hundreds of manufacturers, from UK & Ireland SMBs to global multi-site manufacturers, in wide range of different industries.

Our software works stand alone or as integrated solutions bringing your financial, MRP and production planning systems together in one cloud-based platform.

You can also take advantage of other Access business software such as HR, CRM and payroll.

This gives you the freedom to assemble your business ERP to suit your specific requirements, confident in the knowledge that it has the ability to be scaled up as your business grows

Benefits of Access manufacturing software

- Complete visibility across your business through joined up systems

- Informed decisions based on an accurate, real-time view of business performance

- A stronger cash position with a streamlined quote to cash process

- Increased efficiency and capacity, improved resource utilisation, reduced downtime and WIP

- Manual, paper-based and spreadsheet-based processes reduced or eliminated

Future proof your business with manufacturing ERP software

Manufacturers have faced massive challenges in the past five years including supply chain disruption and rising costs. This is in addition to ongoing challenges such as labour and skills shortages.

Technology plays a critical role in helping businesses be flexible and responsive. With the right software, manufacturers can now delve into a wealth of data and insights to make decisions which optimise their use of labour, equipment and resources, and at a strategic level, shape the future direction of the business.

We can help you design a manufacturing ERP that works for your business.

Our sectors

Martin's Rubber Ltd: enhancing operational efficiency

Martin's Rubber Ltd, a business dating back to 1865 but today at the forefront of high performance rubber-based products for many industries including premium automotive, F1, oil and gas, and more. Hear how Access manufacturing software plays a pivotal role in enhancing their operational efficiency.

See the manufacturing software in action

What our customers say

Manufacturing software

Learn more about our range of software solutions for manufacturing businesses.

Material Requirements Planning (MRP) software

Run your manufacturing operations more effectively with our FactoryMaster software.

Production planning and scheduling

Ensure that you are utilising every machine, employee and resource to its full capacity with our Orchestrate software.

Financial Management Software

Access Financials is our powerful cloud-based financial management software. Integrate with FactoryMaster for exceptional financial visibility.

Customer Relationship Management (CRM software)

If you manufacture products, learn more about how our Prospect CRM software helps you get more customers and a higher customer lifetime value.

Warehouse Management System (WMS)

If you run a wholesale warehousing and distribution operation, learn more about our WMS software.

Inventory Management Software

For instant clarity across suppliers, production, inventory and customers, learn more about our Unleashed software.

Order Fulfillment Software

If you sell directly to consumers through an Ecommerce fulfilment operation, learn more about our Mintsoft software.

Manufacturing blogs and resources

Browse our manufacturing resources for industry insights, best practice guidance and expert opinions.

FAQs

What is manufacturing software?

Manufacturing software refers to a comprehensive suite of computer programs specifically designed to support and streamline various stages of the manufacturing process. It encompasses essential functionalities such as production planning and scheduling, material requirements planning (MRP), inventory management, quality management, shop floor control, supply chain management, and enterprise resource planning (ERP). By leveraging these software solutions, manufacturers can optimise their operations, boost productivity, and achieve enhanced quality control throughout the production lifecycle.

What is manufacturing ERP software?

Manufacturing ERP software is a specialised solution that enables manufacturing companies to efficiently manage their operations. By integrating production planning, inventory management, supply chain management, quality control, financial management, sales, and customer relationship management, ERP streamlines processes and enhances decision-making. It offers real-time visibility into manufacturing processes, optimises productivity, improves inventory management, and reduces costs. A leading example of manufacturing ERP software is Access ERP.

What is cloud manufacturing software?

Cloud manufacturing software is technology available over the internet via an app or web browser.

Cloud manufacturing software optimises workflows and processes, leading to greater operational efficiency. With all information in one place, communication and visibility is greatly improved, delivering more effective decision-making based on near real-time, accurate data.

Servers are usually managed by a third party, who take on the responsibility for security, back ups and equipment and software maintenance.

Why is manufacturing software important for my business?

Running your operations using paper or spreadsheet-based processes limits the growth of your manufacturing business.

Data is more likely to be out of date, inaccurate and available in separate documents and files, making it difficult to have a clear view of what’s actually happening on the shop floor.

Manufacturing software delivers a wide range of benefits, from improved efficiency to optimised use of labour, equipment and materials. It saves time and reduces costs to a significant extent, freeing you up to focus on what adds value and makes an impact on your productivity and profitability.

Why choose Access manufacturing software?

Access manufacturing software has been developed over many years to meet the needs of a wide range of manufacturers.

We have a proven track record of delivering tangible results and providing the foundations for business growth and profitability for manufacturers in the UK, EU and US.

What are the features of manufacturing software?

Manufacturing software can cover a range of features:

- Job estimates and quotes

- Purchase and sales order processing

- Stock control

- Supplier management

- Shop floor data capture

- Quality control

- Job costing

- Traceability

- Production planning and scenario modelling

How do I know which manufacturing software is best for my business?

When choosing manufacturing software, it’s important to not only consider your current requirements but also your future ambitions, to ensure that you’re investing in a system that scales and adapts as you grow and possibly diversify.

Some manufacturing software solutions are designed for specific industries or company size, however you may need certain functionality outside of this.

Scoping is the first step of the process – current issues and systems, business strategy, budget; this helps you build a list of requirements.

The next step is researching options; seek recommendations from peers, review sites and industry media for example. This will help you finalise your requirements, and weight these according to importance.

Assess your shortlist of candidates and request demos to help you decide not only which solution, but also which supplier is the best fit for your business.

Read our article Best Manufacturing Production Scheduling and Planning Software to see the options in the market and which one is best for your business.